Heat-shrink bands

Heat-shrink bands — a disposable packaging element designed to protect and decorate the necks of the bottles, cans, vials, as well as other various products. It is a finished product in both size and shape. Unlike the heat-shrink full sheet, it can be used for the packaging any, even very small, volume of the products. The heat-shrink band is made of a heat-shrinkable PVC film, which has an optimal strength and the heat-shrink properties.

A profitable marketing tool to attract the attention of consumers

Protection of the products from a falsification and an illegal reuse of the containers

Tamper control, including the spontaneous opening during the transportation

Hygienic protection of packaging and products from dust, dirt, moisture and minor damage

Unique design, 100% exclusivity and originality of your products

Scope of application

Distillery and wine production, pharmaceutical industry (vitamins, medicines, dietary supplements), preservation (ketchups, canned vegetables, jams, baby food, juice production), dairy products, household chemicals, car care products, cosmetics, drinking and mineral water, spice production and much more.

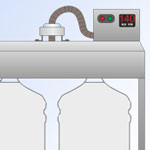

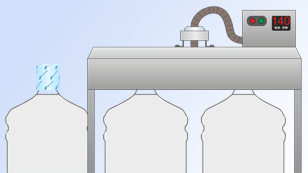

Technology

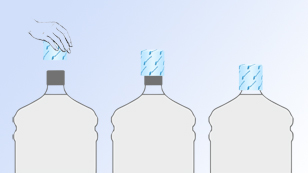

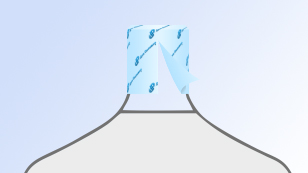

The heat-shrink band is being positioned on the product

Under the influence of temperature, the heat-shrink band shrinks

Opening the shrink band is possible only once

Material, printing technology and advanced options

Custom design for your heat-shrink band

Transparent or colored PVC film, (including a foamed structure)

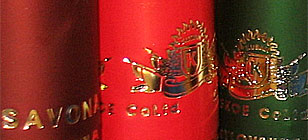

The flexo printing or Rotogravure (gravure) printing up to 8 colors

Glossy or matte surface, velvet effect

Metallic surface and foil stamping

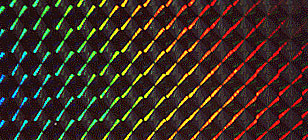

Holographic printing for special product protection

Pasting a holographic or "tobacco" tape

Horizontal and vertical perforation, addition of a tear-off tab

Printed and embossed top disc covering the top of the heat-shrik band

- The permissible spread when printing spot colors on the Pantone Solid Colors (Formula Guide) scale is ±1 of the gradation (inclusive) for the fan, taking into account neighboring fan pages and color serial numbers, depending on what turns out to be a more accurate interval. For colors that are Pantone Solid Colors formulated with more than 50% Transparent Wt. (transparent base) — these are light shades, especially gray ones — the permissible spread is ±2 of the gradations. The above variation is recommended by the German Institute FOGRA (Association for the Study of Printing Technology — Forschungsgesellschaft Drucke. E.V). For example: for blue Pantone 293C, the interval from 2935С to 286С is acceptable, but not the interval from 292С to 294С. On the contrary, for Pantone 327C green, the interval from 326C to 328C is acceptable, and not the interval from 3272C to 320C.

- When printing, mismatch of colors vertically and horizontally up to 1 mm is allowed

Quality

At first glance, it might seem that the heat-shrink band is a very simple product and its quality is unlikely to be very important. But during the application, you may encounter the following problems:

| ill-conceived shape and size of the band | →↓ | poor positioning, incomplete shrinkage, inconvenient removal of the shrink band from the product |

| poor film quality / incorrect film thickness / poor quality perforation | →↓ | incomplete shrinkage, inconvenient removal or premature opening, a large number of defects |

| unadapted image | →↓ | image deformation during shrinkage |

All this can cause a backlash in the eyes of the consumer: the impression may be that the products are fake or made in a "handicraft" way. Practice shows many examples when business executives in pursuit of cost reduction actually lost consumer confidence in their products.

When ordering the heat-shrink bands in our production, you can be sure of the reasonableness of the details and the quality of the finished product.

PackInform

Export of shrink caps to all countries of the world

We export our products to any country. The geography of our customers is constantly expanding due to the high quality of our products, the constant introduction of innovative technological solutions, the competitive prices and large production capacity.