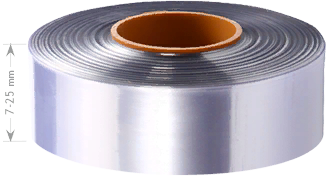

The main difference between narrow seam sleeves is a smaller width (from 7 to 25 mm) compared to classic sleeves. They can be used both for piece and group packaging of goods, as well as for decoration and protection.

Narrow seam shrink sleeve

Scope of use

- cosmetic products (pencils, mascaras, lipsticks, samplers, etc.)

- brushes, pencils and other products for creativity and learning

- test tubes

- mouthpieces, electronic cigarettes

- batteries, rechargeable batteries, capacitors

- electrodes

- gas hoses

- greenhouse arcs

- supports for flowers and plants

- rake rods

- rods of cots

- rods of arbors and fences

Specifications

Decorating and protection

A heat shrink sleeve can completely replace paint, providing a more aesthetic and environmentally resistant coating. The end user can be guaranteed easy care, durability, corrosion protection and many other advantages of the finished product.

Single unit and group packaging

Such packaging can not only protect products, but also give a presentable appearance by replacing the label. Small width allows you to pack even very small types of products. The possibility of delivery in the form of a sleeve or a specific cut will satisfy the needs of production of any scale.

Hygiene protection

Many products are required not only to be packed, but also to be guaranteed a hygienic safety. This is especially important in products intended for children, for example, in the production of children’s holiday mouthpieces.

Ease of use

Packaging can be done automatically or manually, simply by putting on a sleeve or cutting on the product, followed by heating it with a hairdryer or in a heat tunnel.

Narrow seam sleeve application examples

Greenhouse arcs

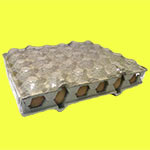

Batteries

Electrodes