- Top disk

- Tear tape

- Thermal stamping

Shrink bands for 5-gallon bottles

Heat-shrink band for 5-gallon bottles has long been an indispensable element in the packaging of these products. Drinking water in multi-turn containers simply needs to be protected as much as possible from unauthorized bottling. You can order a simple transparent cap from us, as well as a cap with various protection technologies and any individual design.

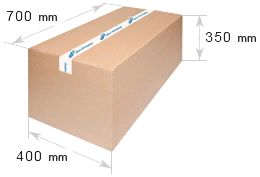

Specifications and packaging

It is possible to produce heat-shrink bands of individual sizes.

Detailed information on printing options, materials, options, quality and technology of application on the page heat-shrink bands

Heat-shrink bands

For those who know the price of their product, for those who are not afraid to declare themselves, for those who want to provide maximum guarantees to their consumers, we have developed a unique product on the packaging market — a shrink band for 19-liter bottles with the unusual options!

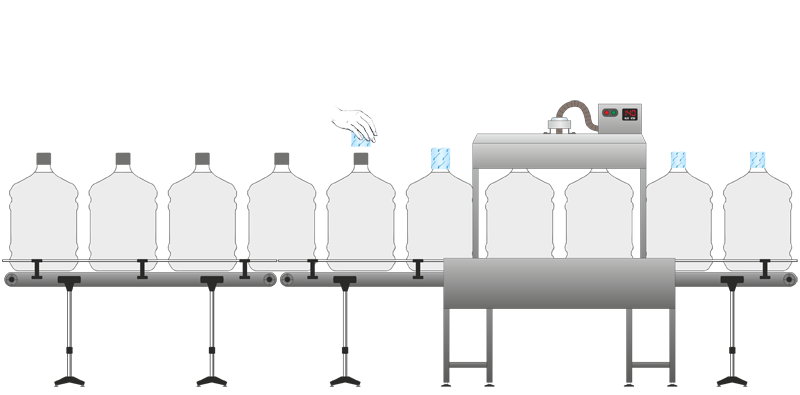

The molded heat-shrinkable band Technology

Due to its excellent shape, the molded heat-shrinkable band manufactured by Don-Polymer ensures easy positioning on the neck of the bottle and, accordingly, high-quality and even sitting. In order to achieve the perfect shrinkage of the PVC shrink band, it is necessary to observe only a few conditions given in this section, as well as storage and transportation rules. If the temperatures at the production and in the warehouse do not coincide, then before starting to use, it is necessary to withstand the boxes with the shrink bands at a usage temperature from 3 to 24 hours (selected empirically).

PackInform

Counterfeit protection

Unlike the disposable containers, the life cycle of the multi-turn 19-liter bottles is repeated many times. This imposes certain obligations on the manufacturer. The most recognized method for most manufacturers is to protect the neck of a bottle with a disposable heat-shrink band.

Hygiene component packaging

Forwarding drivers of water delivery services repeatedly grab the neck with their hands. With the same hands they take money, manage and even repair vehicles, open many door handles. Shrink bands protect the neck from the significant contamination by bacteria, which can subsequently enter the water.

Consumer confidence

It’s no secret that many consumers think that water in multi-turn 19-liter bottles «pours from one barrel.» This stereotype can be broken by a competent approach to creating a positive image of your products.